A well-known pulp and paper company in the Basque Country, Spain, with a long tradition in the manufacturing of colored paper, contacted ITC with the goal of improving and optimizing the dye dosing process available at its facilities.

Improving and optimizing the dye dosing process

Context

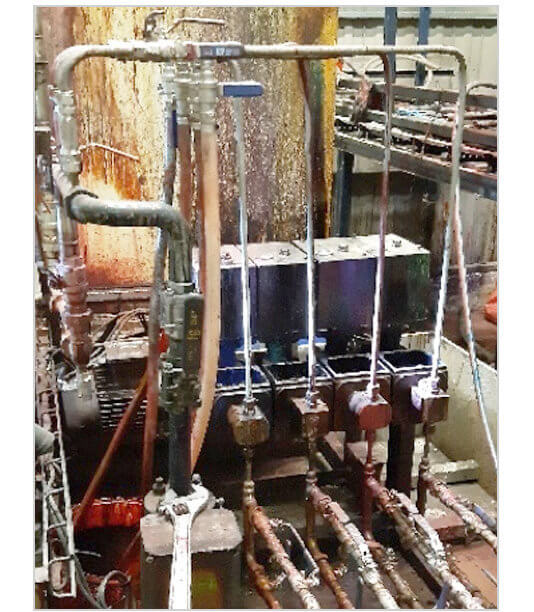

The purpose of the dosing system is to inject 4 dyes (basic colors that can be mixed or not) into the water line of a pulper, a device in which the raw material is introduced to create the paper pulp. With this colorant mixing, different paper hues are obtained following the parameters established by the plant’s SCADA system, which requires extreme precision to manufacture colored paper with totally homogeneous hue.

The existing system does not have an optimal operation and after an analysis carried out by ITC, it is detected that it presents numerous operational and security problems that prevent the system from working regularly and with the desired precision, such as:

Incorrect dimensioning of the suction and discharge hoses. This prevents the pumps from properly suctioning and injecting the viscous products with which they are working. In addition, blockages in the hose frequently occur due to the presence of elements in a reduced section.

Incorrect dimensioning of the suction and discharge hoses. This prevents the pumps from properly suctioning and injecting the viscous products with which they are working. In addition, blockages in the hose frequently occur due to the presence of elements in a reduced section.- Low versatility regarding the different colorant combination needs of the current dosing equipment. It is a pump with four heads driven by a single motor that does not allow dosing a single colorant or stop the other heads.

- Low precision. The current flow control through an external servomotor that regulates the head stroke length does not respond quickly enough to the necessary flow changes.

- Inefficient process control and communication with the client’s own SCADA system. The dosed flow does not consider the water flow into which the colorant is diluted.

ITC Solution

After studying in detail the problems detected in the current system and in coordination with the real needs of the customer, ITC proposes the following changes:

Installation of 4 advanced control DOSTEC AC dosing pumps to independently dose each of the colorants/dyes. The pumps that operate in remote mode are always ready to dose and each one of them receives a parameterization for each of the required and/or formulated colors. This results in a very notable improvement in dosage precision and response time.

Installation of 4 advanced control DOSTEC AC dosing pumps to independently dose each of the colorants/dyes. The pumps that operate in remote mode are always ready to dose and each one of them receives a parameterization for each of the required and/or formulated colors. This results in a very notable improvement in dosage precision and response time.- The system in general is improved, especially regarding the mixing process to be carried out, since the water flow control is improved (which is associated with the customer’s DCS) to obtain extremely precise dye mixtures. Accessories such as calibration cylinders (which provide a more accurate precision) and back pressure valves are installed to be able to maintain the quantity of dye dosed within the minimum error.

- Other improvements include properly dimensioned hoses depending on the flow rate, which allows reducing the significant pressure drop caused by handling highly viscous products. In addition, ITC installs a piping system that allows cleaning the circuit with hot water, providing two advantages. On the one hand, it helps the interchangeability of the pumps (for the handling of future colors and new hues) and, on the other hand, it keeps the circuit in perfect operability condition.

- Safety devices are installed to avoid any eventual overpressure in the network. Additionally, the pump alarm itself allows the central control system to receive warnings in the event of any discharge failure.

Improvements in the installation of the dosing equipment based on DOSTEC AC pump allow more precise coloring and provide the customer with a significantly more reliable and safe system, reducing operating and maintenance costs.

Location

- Basque Country, Spain

Key Points

- Incorrect dimensioning of the suction and discharge hoses

- Low versatility regarding different color combination needs

- Low precision in flow control through external servomotor

- Inefficient process control